- January 13, 2026

- Metal Building Maintenance Tips

- Carports Advisor

What No One Tells You About Metal Building Lifespans?

Many people have misconceptions about the lifespan of a steel structure. It happens because they read about the building from various sources, even from unauthenticated ones. Our team has researched and come up with crucial details to clear off the fog, so you have no more confusion. Many buyers believe that once a metal building is installed, it will stand strong for life with little effort. Well, that’s true, but only to some extent and under certain conditions.

We will tell you all about these conditions, and mostly what no one tells you about steel structures. This blog uncovers those details honestly, without marketing fluff, so that you can make informed decisions.

Are you ready for the truth?

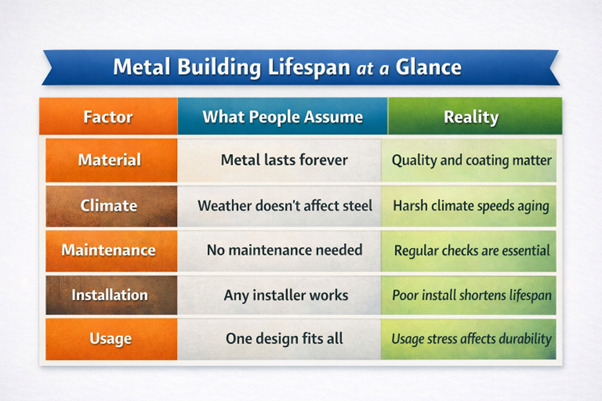

What People Usually Think About Metal Building Lifespan

Most people approach metal buildings with strong assumptions. These beliefs often come from people who were proactive during the structure’s customization and installation, and, most importantly, from their experience choosing the right prefab building dealer. One common mindset is that “metal doesn’t rot, so it must last forever.” While it’s true that steel doesn’t rot like wood, it can still weaken, corrode, or fail if ignored. This belief causes many owners to overlook planning and maintenance.

Marketing also plays a role. Sellers highlight durability but rarely explain the conditions required to achieve it. In reality, lifespan depends on more than materials alone. Design quality, installation, environment, and usage all shape how long a building truly lasts. Understanding this gap between belief and reality helps us move toward a more honest view of the longevity of metal buildings.

The Real Average Lifespan of a Metal Building

Once expectations are set aside, it’s easier to talk about real numbers. Metal buildings do last long, but not endlessly without care.

On average, a properly designed and maintained metal building lasts 30 to 50 years, and sometimes longer. Buildings in mild climates with good upkeep can even cross the 60-year mark. On the other hand, poorly installed or neglected structures may show serious issues in under 20 years.

It’s also important to understand the difference between structural life and appearance life. A building may still be safe and usable even if paint fades or panels look worn. Many owners confuse visual aging with structural failure, which leads to unnecessary concern or incorrect assumptions. This lifespan range becomes clearer once we understand the factors that truly control durability.

Factors That Truly Decide How Long a Metal Building Lasts

Steel buildings don’t fail randomly. Their lifespan is shaped by specific, controllable factors. Ignoring these details is where most long-term problems begin.

1. Quality of Steel and Coating:

The strength of a metal building starts with the steel itself. Thicker steel panels offer better resistance to bending, dents, and long-term stress. Lower-quality steel may reduce upfront cost, but it also shortens lifespan. Protective coatings matter just as much. Galvanization and high-quality paint protect steel from moisture and UV damage. Without these layers, exposed metal slowly corrodes, even in moderate climates. Understanding the detailed anatomy of the frame, truss, and girt helps buyers see why quality materials are not optional. Every part works together to carry loads and resist environmental pressure.

2. Climate and Location:

Climate plays a major role in how fast a metal building ages. Buildings in dry areas usually last longer than those exposed to moisture, salt, or extreme temperature changes. High humidity and rainfall increase rust risk, while snow adds constant weight stress to roofs. Coastal air contains salt, which accelerates corrosion even on coated steel. Strong sunlight also breaks down paint and protective layers over time. This is why location should always guide design choices. Ignoring environmental impact is one of the biggest reasons buildings age faster than expected.

3. Foundation and Installation Quality:

A strong building still depends on a strong base. If the foundation is uneven or poorly designed, stress spreads unevenly through the structure. Incorrect installation can lead to leaks, shifting frames, and early wear. Even small alignment mistakes grow into bigger problems over time. This is why professionals stress the importance of taking time to prepare your site properly before installation. A solid foundation doesn’t just support weight; it protects the entire structure’s lifespan.

Maintenance Truths No One Talks About

After installation, maintenance becomes the silent factor that decides how long a metal building survives. Unfortunately, this part is often ignored. Metal buildings are often labeled “low maintenance,” but many people misunderstand this. LOW maintenance does mean NO maintenance. It simply means fewer tasks compared to wood or brick structures. Regular inspections help identify rust spots, loose fasteners, or water pooling early. Cleaning dirt and debris prevents moisture buildup. Small repairs done on time are far cheaper than large fixes later. Maintenance doesn’t add hassle; it adds years to your building.

Common Reasons Metal Buildings Fail Early

When metal buildings fail early, it’s rarely due to steel weakness alone. In most cases, failure comes from neglect or misuse. Rust is the most common issue. When coatings are damaged and not repaired, moisture attacks exposed steel. Over time, rust spreads and weakens panels and connections. Water pooling is another major problem. Poor drainage allows water to sit on roofs or around the base, increasing the risk of corrosion and leaks. Structural overload, especially snow or added equipment, also causes premature failure. These problems often connect directly to how the building is used.

How Usage Affects Lifespan:

Usage patterns influence lifespan more than many owners realize. A lightly used storage building ages very differently from a busy commercial workspace. Storage structures experience minimal daily stress, while workshops and commercial buildings handle constant movement, vibration, and heavy equipment. Residential garages fall somewhere in between. Internal wear, repeated door usage, and unplanned modifications also reduce lifespan.

Example: Converting a basic shelter into a storm-proof carport requires proper reinforcement. Without it, stress builds where the structure wasn’t designed to handle it. Using a building beyond its original design always shortens its life.

Then, How to Extend the Life of a Metal Building?

The good news is that lifespan can be extended with smart choices. Prevention always costs less than repair. Designing correctly from the start makes a huge difference. Choosing the right size for a metal garage or any other steel structure prevents overloading and unnecessary stress. Proper drainage systems and protective features also help.

Equally important is choosing a reliable dealer and installer. Quality workmanship ensures correct installation, material selection, and long-term support. This is a major reason why businesses trust metal carports for long-term operations. Most of these structures are planned, not rushed. Smart planning adds decades of usability.

Honest Opinion: Are Metal Buildings Worth It Long-Term?

From a long-term perspective, metal buildings are absolutely worth it when chosen wisely.

They offer excellent durability, fire resistance, and pest protection compared to many traditional materials. When properly installed and maintained, they outperform wood and many masonry structures in lifespan.

However, buyers must avoid mistakes while buying. Cheap materials, rushed installation, and ignoring climate factors quickly reduce value. Focus on making informed decisions because that is what turns prefabricated buildings into long-term assets.

The Truth Is in the Details

Metal buildings don’t last forever on their own. Their lifespan depends on the quality of the steel, correct installation, proper use, and regular care. When buyers understand these details, they stop relying on assumptions and start making smarter choices. The result is a building that stays strong, functional, and valuable for decades. In the end, longevity is not about metal alone; it’s about how thoughtfully everything comes together.